In the production of striped shirting fabrics, fine cationic yarns can sometimes cause weft contamination, affecting the overall appearance and quality of the fabric. Understanding why this happens—and how to prevent it—is essential for ensuring stable weaving performance.

In this article, we explore the main causes of weft defects in cationic stripe fabrics and provide practical solutions that can be applied both during production and inspection, helping manufacturers maintain high-quality results.

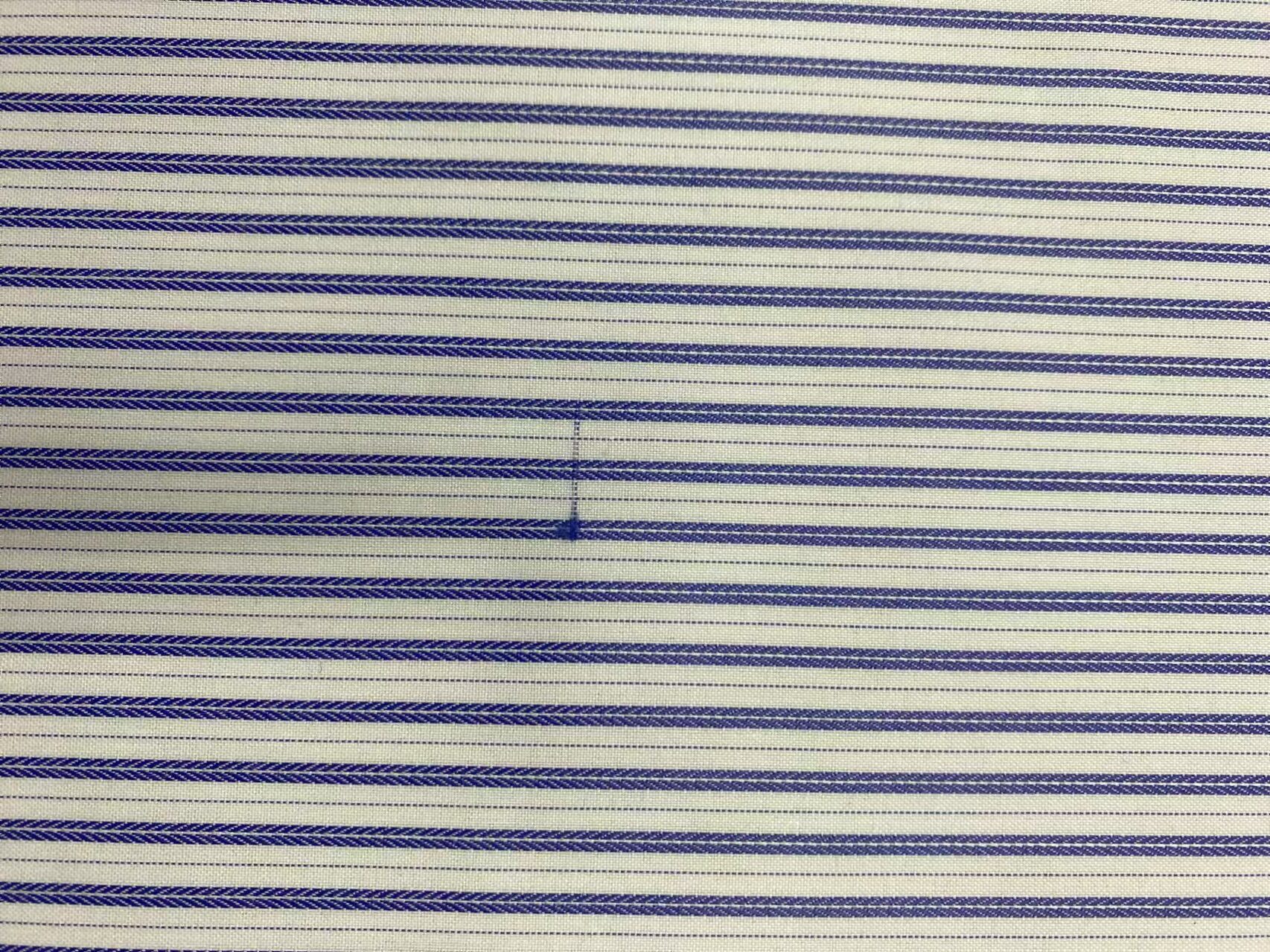

Fabric Structure and Observed Issue

Warp yarn: White 80S/2 CVC (60/40)

Stripe yarn: 75D/72F cationic polyester

Defect location: Areas where cationic fibers are carried into the weft

During weaving, some cationic fibers are carried into the weft direction during the beat-up process. The main cause is the fine and fluffy nature of the cationic filament, which makes it unstable during weaving—a common issue when using ultra-fine yarns.

Practical Solutions

Apply light twist to the cationic filament to improve yarn stability.

Select slightly coarser cationic yarns instead of ultra-fine ones to reduce fiber movement.

Correct during inspection: If the defect has already appeared, experienced fabric inspectors can remove the weft-direction foreign fibers through mending to minimize impact on finished fabric.

Key Takeaways

Early identification and understanding of weaving defects is crucial for consistent fabric quality.

Combining proper yarn selection with professional finishing and inspection ensures durable, high-quality shirting fabrics.

Even small adjustments in yarn handling can significantly reduce defects and improve customer satisfaction.

We focus on both innovative fabric development and practical production solutions to ensure our fabrics meet the highest standards in quality, appearance, and performance.