Understanding Pigment Spots in Light-Colored Fabrics

Causes, Limitations, and Prevention in the Heat-Setting Process

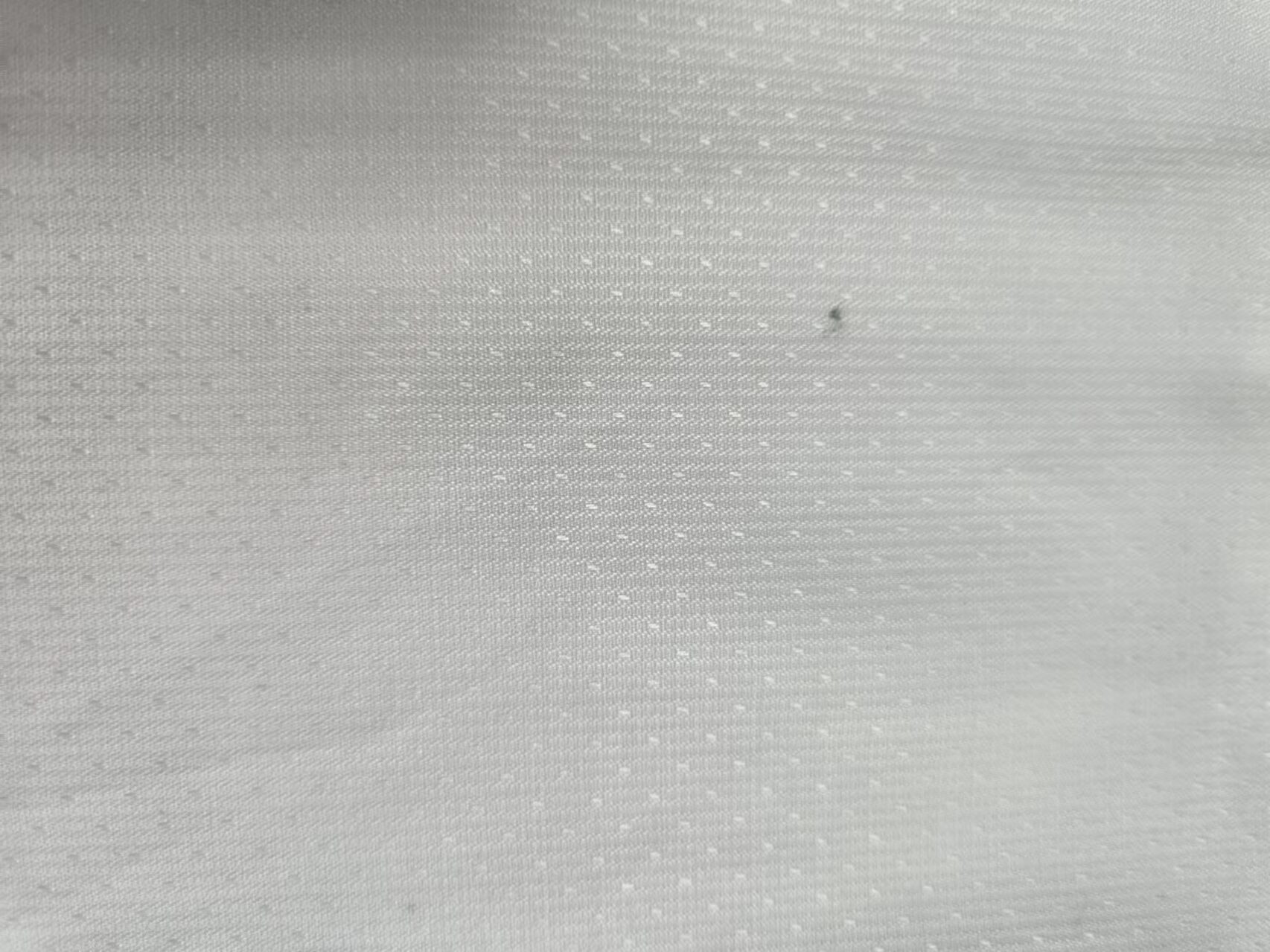

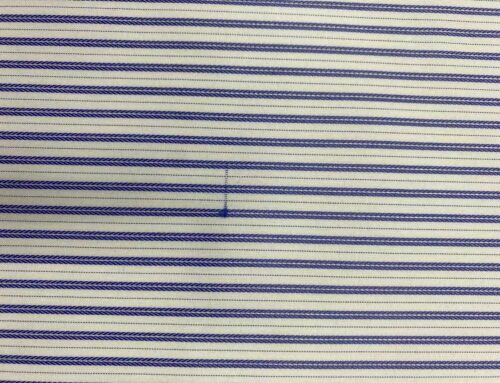

In fabric production, “pigment spots” — commonly referred to in the industry as color specks — are a quality issue that can occasionally appear after dyeing and heat-setting.

These spots are especially noticeable on light-colored fabrics, particularly white or pastel shades. Due to their contrast against the base color, even minor pigment residues can significantly affect the visual quality of the fabric.

Why Do Pigment Spots Occur?

Pigment spots are typically formed during the post-dyeing heat-setting process. Residual dye particles or unstable color components may migrate and fix onto the fabric surface under high temperature conditions.

While darker fabrics can sometimes mask these imperfections, light shades make them immediately visible.

Why Are They Difficult to Fix?

Once pigment spots appear, correction becomes challenging:

Physical removal during fabric inspection is usually ineffective.

Chemical spot treatment after finishing rarely delivers stable results.

The only reliable solution is chemical stripping at the dyeing mill.

However, chemical stripping:

May cause certain damage to the fabric

Can affect hand feel and strength

Cannot be repeated multiple times

For this reason, prevention is far more important than correction.

Prevention Is the Key

To minimize the risk of pigment spots, special attention must be given during the heat-setting stage:

Careful monitoring of dyeing quality before setting

Strict process control during temperature adjustment

Clear separation of color groups

Tailored follow-up procedures for different color systems

In fabric production, technical awareness at each stage makes the difference between reactive correction and proactive quality control.

By focusing on preventive process management, we ensure consistent appearance and stable quality — especially for light-colored shirting fabrics where detail matters most.