Avoid Shrinkage Issues in Shirting Fabrics: Key Factors You Must Know

Introduction

You buy a shirting fabric, check it in the shop, and it feels perfect. But after washing a few times, it shrinks or stretches. Why does this happen? Understanding the reasons behind fabric shrinkage is essential for both manufacturers and buyers to ensure consistent quality and garment fit.

1️⃣ Raw Material Matters

The shrinkage behavior depends heavily on fiber type:

Natural fibers like cotton, linen, and regenerated cellulose fibers (viscose, modal, bamboo) absorb water, swell, and can shrink significantly.

Synthetic fibers such as polyester or polyamide absorb little moisture, so shrinkage is minimal.

Wool has scales on its surface, which can cause felting and dimensional instability.

Practical tip: Choose fiber types carefully for the desired dimensional stability. Blending fibers can help balance softness and shrinkage control.

2️⃣ Fabric Density

Higher density fabrics tend to shrink less, as yarns are tightly packed and resist movement.

Fabrics with lower density allow more yarn movement, resulting in higher shrinkage.

Tip: Adjust fabric density based on the shrinkage tolerance required for the garment.

3️⃣ Yarn Count

Coarse yarn fabrics can shrink more in bulk production due to larger fiber swelling.

Fine yarn fabrics are generally more stable.

Tip: Consider yarn count when designing fabrics for shrink-sensitive garments.

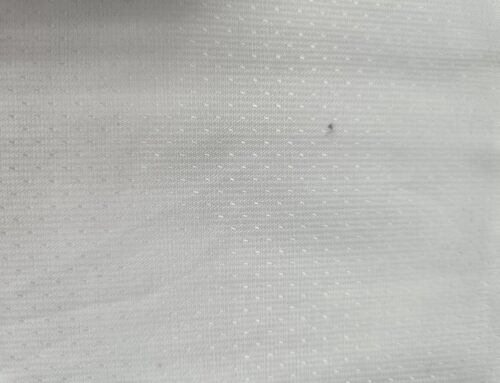

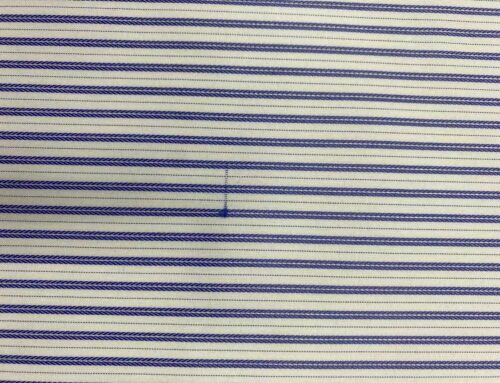

4️⃣ Fabric Structure

Woven fabrics are generally more stable than knitted fabrics.

In woven fabrics: plain weave shrinks less than twill or flannel.

In knitted fabrics: flat needle fabrics shrink less than ribbed fabrics.

Tip: Choose the right weave/knit structure depending on desired shrinkage performance.

5️⃣ Production & Processing

During weaving, dyeing, printing, and finishing, fabrics experience tension:

Fibers stretch under machine tension, creating internal stress.

After washing, the stress relaxes, causing shrinkage.

Tip: Pre-shrink fabrics where necessary. Monitor machine tension, and control heat-setting carefully.

6️⃣ Washing & Care

Washing temperature, method, drying, and ironing all influence shrinkage.

Hand washing is generally gentler than machine washing.

Drying methods matter: drip drying < hanging < flat drying < rotary drying (most impact).

Tip: Provide washing care instructions to maintain dimensional stability.

Conclusion

Shrinkage is a natural result of fiber swelling, fabric structure, and processing tension. For bulk production, understanding these factors is essential:

Plan fiber selection, yarn count, and weave structure carefully.

Control production tension and heat-setting.

Provide proper washing and care guidance.

By addressing shrinkage at each stage—from design to finishing—you ensure garments meet specifications and remain comfortable for end users.

By Shirly Xia

Fabric Development | Shaoxing Wuyue Textile Co., Ltd.

Published: 2026-02-12